RESEARCH

Nanocrystal : Fundamental aspects related to synthesis and growth process

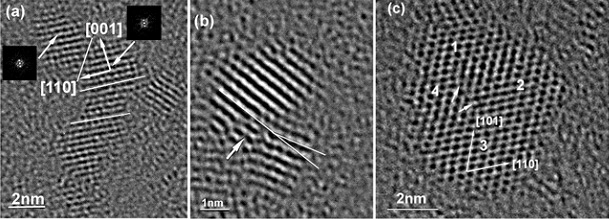

A detailed analysis of the crystal growth mechanism during the synthesis process is fundamental to control the size and shape of nanocrystals and anisotropic nanostructures. The oriented attachment (OA) mechanism originally proposed by Banfield and Penn (Science 1998, 281, 969-971) is a process involving the self-organization of adjacent nanocrystals and coalescence. The number of materials obtained by the OA process has been growing rapidly and has become an attractive and important form of processing nanomaterials with anisotropic structure.

In our research group we are developing new chemical synthesis approach, based on non-hydrolic sol-gel process, to obtain ceramics oxides (SnO2, TiO2, Fe3O4 , ZrO2 , ITO, CeO2 and others). We are also working hard also in the modification of the nanocrystal chemical surface and analyzing how these new surfaces modify the growth process (mainly the OA process) and the nanocrystal solubility.

A detailed analysis of the crystal growth mechanism during the synthesis process is fundamental to control the size and shape of nanocrystals and anisotropic nanostructures. The oriented attachment (OA) mechanism originally proposed by Banfield and Penn (Science 1998, 281, 969-971) is a process involving the self-organization of adjacent nanocrystals and coalescence. The number of materials obtained by the OA process has been growing rapidly and has become an attractive and important form of processing nanomaterials with anisotropic structure.

In our research group we are developing new chemical synthesis approach, based on non-hydrolic sol-gel process, to obtain ceramics oxides (SnO2, TiO2, Fe3O4 , ZrO2 , ITO, CeO2 and others). We are also working hard also in the modification of the nanocrystal chemical surface and analyzing how these new surfaces modify the growth process (mainly the OA process) and the nanocrystal solubility.

Nanocomposites: Development of Molecular Composites

For most current applications of plastics, performance requirements, as well as cost and processing consideration, necessitate the incorporation of additives and fillers into the polymeric matrices. The use of nanostructured fillers push this strategy to the next level by exploiting the advantages that nanometer-size particles offer compared with traditional fillers. Most of the research efforts of polymer-based nanocomposites to date have revolved around introducing nanostructured fillers into polymers capitalizing on the filler properties to enhance performance of the composite. This traditional procedure produces a class of materials that can be described by the term " nano-filled polymer". However, in order to obtain a "true" nanocomposite, it is necessary to induce new physical properties, or functionality, that are absent in the polymeric matrix.

This "true" nanocomposite can be classified as a novel class of materials and can be termed as "molecular composite".

This new class of

composite demand the development of new synthetic routes that allows a selective reinforcing of a specific domain in a phase separated block copolymer.

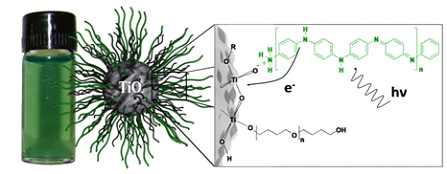

In our research group we are developing molecular composite, using the colloidal synthesis approach, with functional properties, based on polyurethane (PU) and oxide nanocrystals (ON). The functionality of the composite is tailored by the control of the ON properties. For instance, in order to obtain a magnetic molecular composite, a magnetic nanocrystal is used.

For most current applications of plastics, performance requirements, as well as cost and processing consideration, necessitate the incorporation of additives and fillers into the polymeric matrices. The use of nanostructured fillers push this strategy to the next level by exploiting the advantages that nanometer-size particles offer compared with traditional fillers. Most of the research efforts of polymer-based nanocomposites to date have revolved around introducing nanostructured fillers into polymers capitalizing on the filler properties to enhance performance of the composite. This traditional procedure produces a class of materials that can be described by the term " nano-filled polymer". However, in order to obtain a "true" nanocomposite, it is necessary to induce new physical properties, or functionality, that are absent in the polymeric matrix.

This "true" nanocomposite can be classified as a novel class of materials and can be termed as "molecular composite".

This new class of

composite demand the development of new synthetic routes that allows a selective reinforcing of a specific domain in a phase separated block copolymer.

In our research group we are developing molecular composite, using the colloidal synthesis approach, with functional properties, based on polyurethane (PU) and oxide nanocrystals (ON). The functionality of the composite is tailored by the control of the ON properties. For instance, in order to obtain a magnetic molecular composite, a magnetic nanocrystal is used.

Alternative Energy: Polyelectrolyte and Hydrogen Generation

The main problem facing new energy conversion and storage technologies remains device efficiency. Projects based on nanostructured materials can yield improved performance in devices involving electrochemical reactions and heterogeneous catalysis, such as fuel and solar cells, batteries, etc. Nanoscale structures dramatically alter the surface reaction rates and electrical transport throughout the material, causing a dramatic improvement in energy storage, conversion and generation. Furthermore, the design of nanoscale materials to can be applied in alternative energy devices is a predictable way to develop a wide range of new technologies for a more sustainable future.

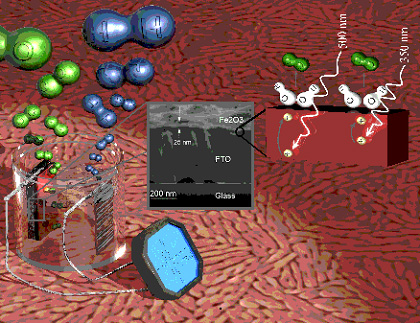

Our research group is developing new polyelectrolyte materials based on a hybrid polymer with physical and chemical properties interesting . We are working also in the development of nanostructure hematite thin films in order to promote the water-splitting by light. The Iron oxide (a-Fe2O3 or Hematite) is a semiconductor material with a narrow band gap (approximately 2.2 eV) and very good electrochemical stability in water. These properties make this material especially attractive when used as photoanode to split the water into oxygen and hydrogen by sunlight.

The main problem facing new energy conversion and storage technologies remains device efficiency. Projects based on nanostructured materials can yield improved performance in devices involving electrochemical reactions and heterogeneous catalysis, such as fuel and solar cells, batteries, etc. Nanoscale structures dramatically alter the surface reaction rates and electrical transport throughout the material, causing a dramatic improvement in energy storage, conversion and generation. Furthermore, the design of nanoscale materials to can be applied in alternative energy devices is a predictable way to develop a wide range of new technologies for a more sustainable future.

Our research group is developing new polyelectrolyte materials based on a hybrid polymer with physical and chemical properties interesting . We are working also in the development of nanostructure hematite thin films in order to promote the water-splitting by light. The Iron oxide (a-Fe2O3 or Hematite) is a semiconductor material with a narrow band gap (approximately 2.2 eV) and very good electrochemical stability in water. These properties make this material especially attractive when used as photoanode to split the water into oxygen and hydrogen by sunlight.

Understanding Thermal Stability of Ceramics Nanosystem

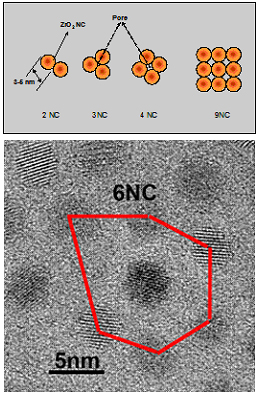

Considering that crystal growth, in the solid state is controlled by the motion of the boundaries between particles, one can assume that the average boundary velocity, n, is proportional to the thermodynamic driving force, DF, applied to it, i.e., n = MDF; where M is particle boundary mobility, which depends on the mechanism of diffusion (a kinetic parameter). Thus, two distinct approaches can be used to control the crystal growth: a) reduction of DF (thermodinamics approach); b) reduction of crystal boundary mobility (kinetics paramters). A question still opened in materials science is whether the growth mechanism valid for micrometric solids will be the same for the nanometric material. This question is important if we bear in mind that in materials with dimensions below 10nm most of the atoms are located in the surface. This research project addresses this question and will try to answer it developing synthesis and assembly methods to process metal oxide nanocrystal (ceramics nanocrystals) as well as using in situ transmission electron microscopy (TEM) and high resolution transmission electron microscopy (HRTEM) characterization. In this project, we aim to contribute for the basic understanding of the particle growth and pore elimination process (sintering process) of ceramics nanosystems by developing and applying new experimental procedure that will allow a controlled synthesis and deposition of monodisperse ceramic nanocrystals (particle size in the range of 3 to 5 nm) and their in situ TEM/HRTEM sintering characterization.

Considering that crystal growth, in the solid state is controlled by the motion of the boundaries between particles, one can assume that the average boundary velocity, n, is proportional to the thermodynamic driving force, DF, applied to it, i.e., n = MDF; where M is particle boundary mobility, which depends on the mechanism of diffusion (a kinetic parameter). Thus, two distinct approaches can be used to control the crystal growth: a) reduction of DF (thermodinamics approach); b) reduction of crystal boundary mobility (kinetics paramters). A question still opened in materials science is whether the growth mechanism valid for micrometric solids will be the same for the nanometric material. This question is important if we bear in mind that in materials with dimensions below 10nm most of the atoms are located in the surface. This research project addresses this question and will try to answer it developing synthesis and assembly methods to process metal oxide nanocrystal (ceramics nanocrystals) as well as using in situ transmission electron microscopy (TEM) and high resolution transmission electron microscopy (HRTEM) characterization. In this project, we aim to contribute for the basic understanding of the particle growth and pore elimination process (sintering process) of ceramics nanosystems by developing and applying new experimental procedure that will allow a controlled synthesis and deposition of monodisperse ceramic nanocrystals (particle size in the range of 3 to 5 nm) and their in situ TEM/HRTEM sintering characterization.